The History

Of

Autowrappers

Part 5

The Whiffler Road Factory,

Auto Wrapper (Norwich) Ltd

The Tobenoil years

1966 to 1976

The

Company

was

now

part

of

the

TOBENOIL

group,

and

by

1964

a

larger

premises

was

required

due

to

the

increasing

demand

for

the

machines,

a

site

at

Whiffler

Road

was

found,

plans

were

drawn

up

and

planning

permission

was

granted

on

the

14th

of

January

1965,

at

the

time

it

was

on

the

very

outskirts

of

Norwich

surrounded by open fields, but as Norwich grew so did the surrounding industry around the Autowrappers factory.

A new era followed ......

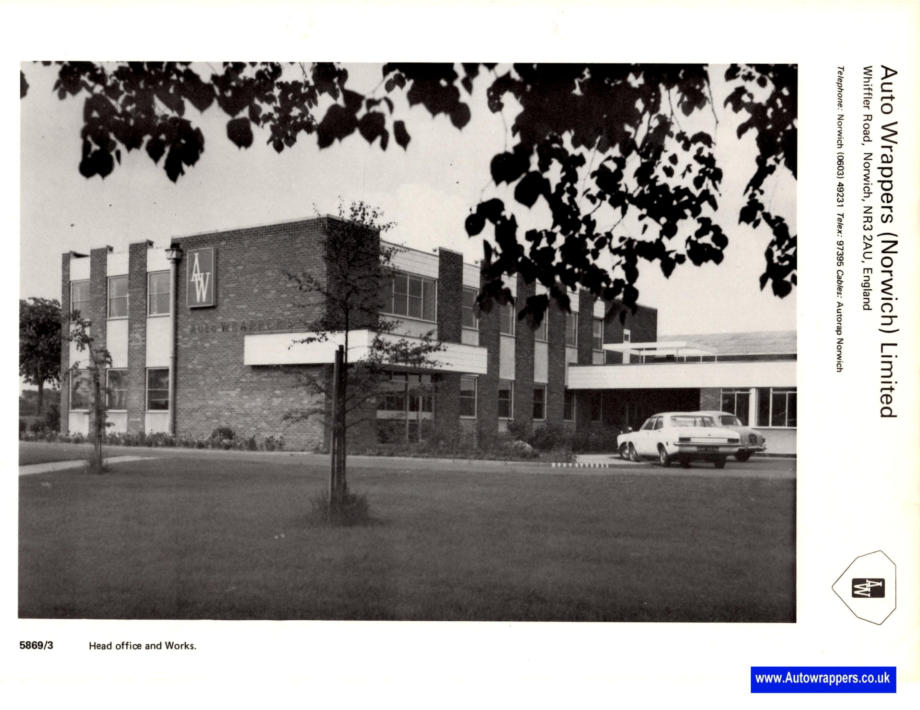

Photo Ref: AW0048 Whiffler Road Factory Main office building ( 1967 )

Photo Ref: AW0029 Whiffler Road Factory from above (1967)

And for comparison here is what the same area looks like today (2016)

More views of the Whiffler Road factory

Photo Courtesy of Richard Rush and Trevor Kirby

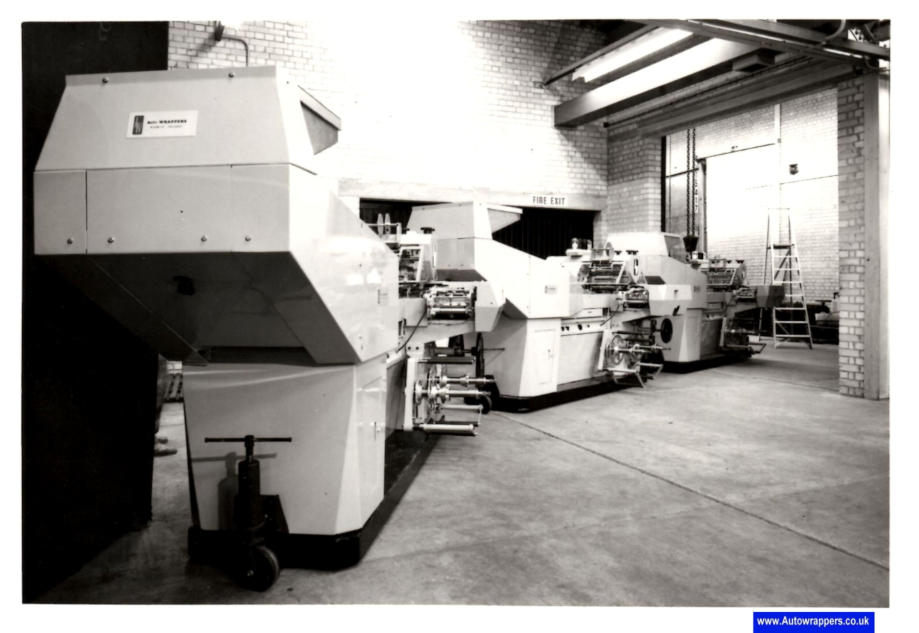

Photo Ref: AW0228

Photo Ref: AW0233

Photo Ref: AW0225

Photo Courtesy of Richard Rush and Trevor Kirby

As

the

industry

around

Norwich

and

the

rest

of

the

UK

grew,

so

did

the

demand

for

wrapping

machines,

this

required

a

larger

work

force,

after

only

3

years

at

the

new

site,

the

factory

was

running

at

capacity,

By

1968

it

was

decided

to

expand

the

factory

area

from

40,000

Sq

Ft

to

75,000

Sq

Ft

,

with

an

aditional

3,300

Sq

Ft

added

to

accommodate extra office space

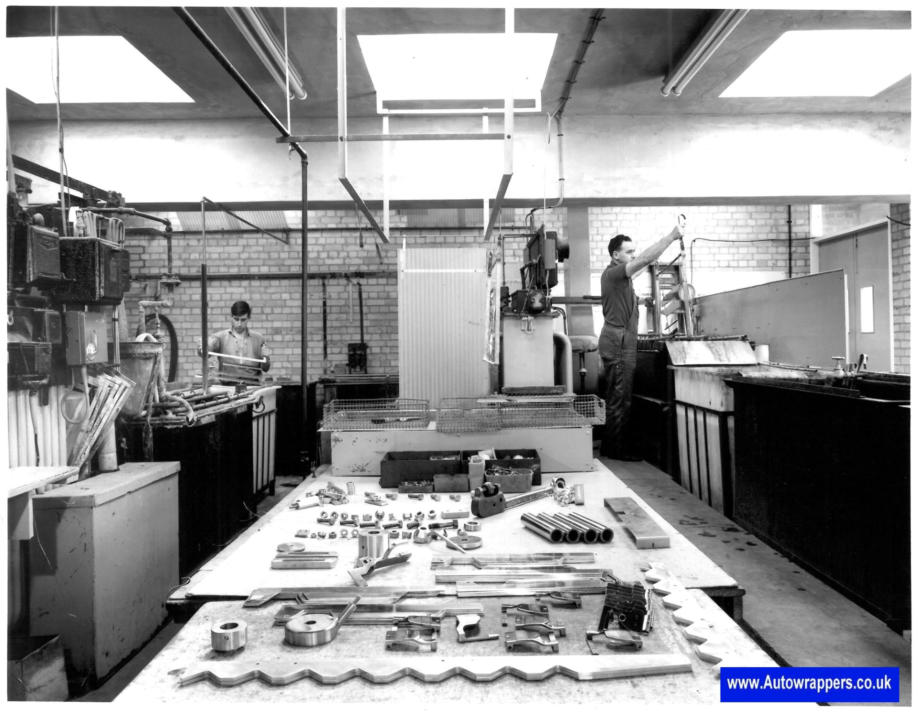

The

factory

was

self-sufficient

with

every

component

being

made

in

the

vast

machine

shops

by

highly

skilled

engineers,

with

the

addition

of

paint

shops

and

plating

shops

the

whole

manufacturing

process

was

self-contained

and efficiently run.

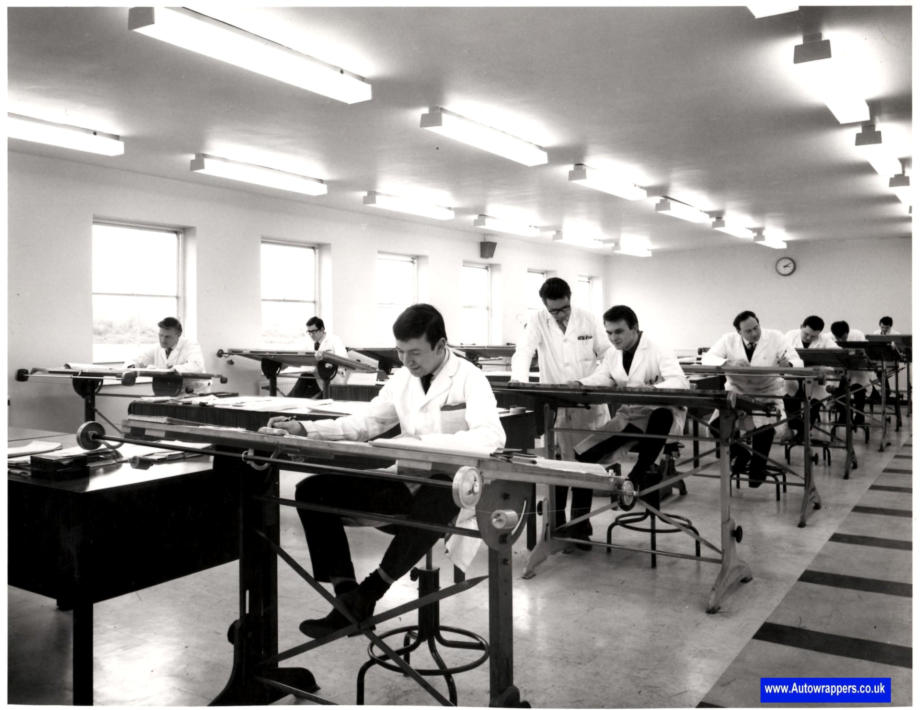

A new state of the art design and drawing office with was created and still not a computer in sight

Photo Ref: AW0227 Photo Courtesy of Richard Rush and Trevor Kirby

Individual components being made in the machine shop at Whiffler Road

Photo Ref: AW0044 Whiffler Road Machine shop

After each component is manufactured, it then passes through the inspection department that checks that it is

dimensionally correct and meets the required tolerances.

Photo Ref: AW0226

Photo Courtesy of Richard Rush and Trevor Kirby

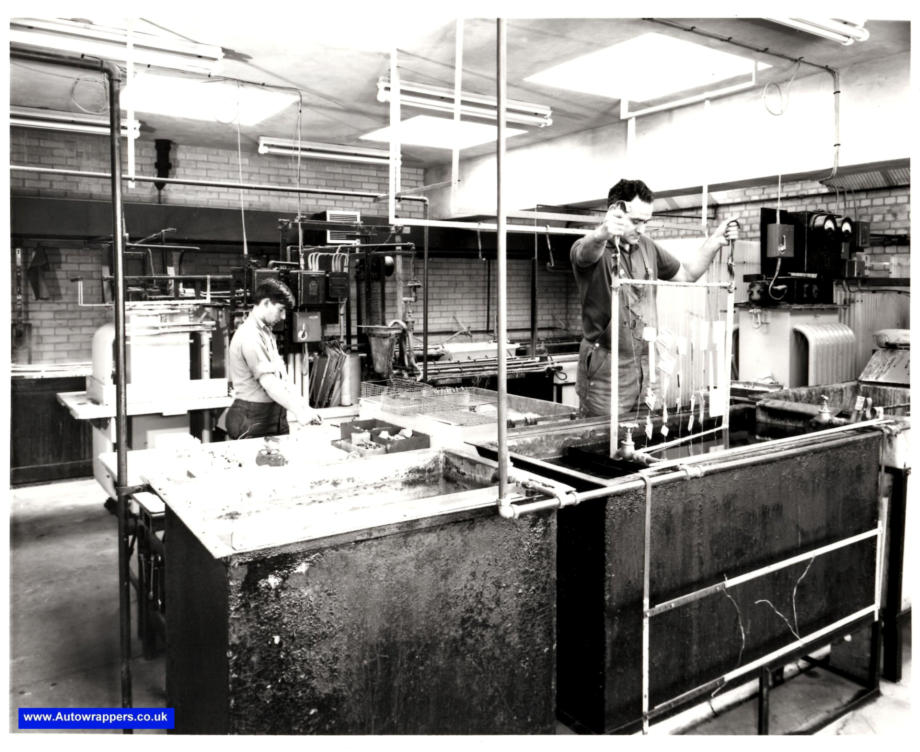

After

the

components

are

inspected

some

parts

may

be

required

to

be

plated

to

prevent

corrosion,

usually

zinc

or

chrome

plating

was

used.

most

of

the

plating

equipment

shown

here

at

whiffler

road

plating

shop

was

the

original

plating equipment first used in the Nissan Hut back in the late 40s ( see earlier history section )

Photo Ref: AW0223 Photo Courtesy of Richard Rush and Trevor Kirby

Photo Ref: AW0046 The Whiffler Road Plating Shop

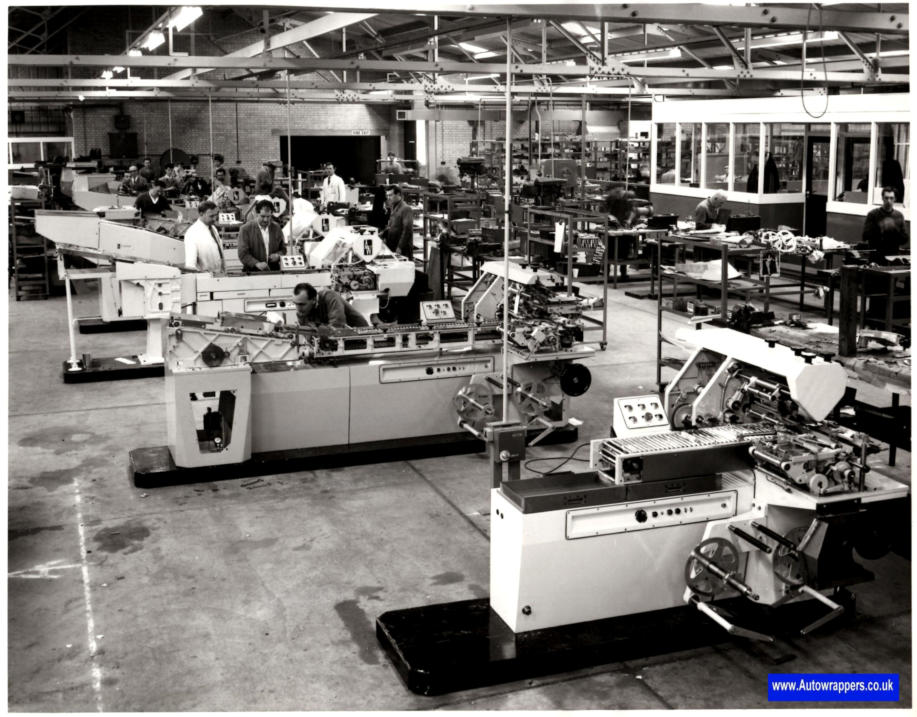

Once

the

components

are

complete

and

ready,

assembly

begins

on

the

assembly

shop

floor

and

the

machines

start

to

take

shape.

below

is

an

early

photo

from

whiffler

road

as

most

of

the

Roll

wrappers

were

of

the

original

"R"

type.

Photo Ref: AW0232 Photo Courtesy of Richard Rush and Trevor Kirby

Below

is

a

later

photo

at

Whiffler

Rd

and

shows

Rows

of

Super

2000

Roll

Wrappers

in

various

stages

of

construction. the R type machines were gradually phased out by the end of the 60s

The following information was sent to us by Rod Horne

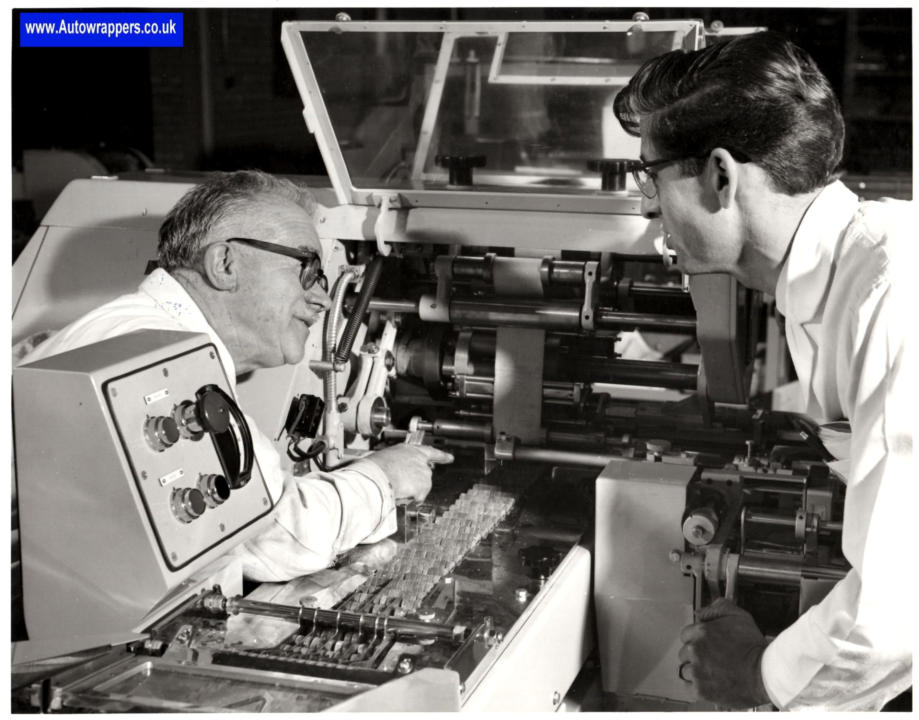

In

the

photo

below

the

man

leaning

into

the

machine

was

Frank

Oakley.

I

worked

for

a

couple

of

years

with

Frank

as

part

of

my

training.

At

that

time

John

Plumstead

was

the

leading

hand

before

becoming

more

involved

with

development.

Frank

and

I

got

on

well

and

my

wife-to-be

and

I

socialised

with

Frank

and

his

wife

Nancy.

I

saw

Nancy

in

two

photographs,

AW0077

and

AW0120.

I

believe

Frank

died

in

the

late

60s

but

by

then

we

had

drifted

apart

and

I

learned

of

his

death

by

chance.

They

came

to

our

wedding. Also

in

the

same

picture

is

David

Garnett.

David and I were apprentices together although he was maybe a couple of years older.

Photo Ref: AW0234 Photo Courtesy of Richard Rush and Trevor Kirby

After

construction

each

machine

is

individually

tested

to

make

sure

that

it

meets

the

required

performence

level

and

customer

quality

expectations.

The

photo

below

shows

Jack

Robinson

and

Dennis

Smith

overseeing

the

testing of a Super 2000.

We were sent the following information by Rod Horne

The

man

on

the

left

was

one

Jack

Robinson

who

was

foreman

of

the

R

machine

section

during

my

time

at

AW.

Jack

was

from

the

north

of

England,

and

had

some

quaint

expressions

one

being

“arris”

for

sharp

edge

so

you

would

be

told

to

get

a

file

a

remove

the

arrises

from

something.

He

once

told

a

fitter,

Eddie

Trowse,

that

he

should

be behind a plough. Eddie, never at a loss for words said “… and you should be pulling it.”

Photo Ref: AW0231 Photo Courtesy of Richard Rush and Trevor Kirby with aditional info from Rod Horne

After testing..... the machines make thier way to the dispatch area where they are crated and loaded on trucks for

dispatch to the customers.

Photo Ref: AW0246 Photo Courtesy of Richard Rush and Trevor Kirby

The Rise of the Flow-Wrapper

At

this

time

Flow-Wrapping

was

the

next

big

thing,

more

customers

wanted

this

type

of

packaging,

Autowrappers

entry

into

the

Flow-wrapping

market

in

the

early

60s

had

been

successful

with

the

AT

machine

and

the

Flow-wrap

market

was

growing

rapidly,

and

due

to

this

demand

Swiss

packaging

manufacturer

SIG

Pack

(

Now

owned

by

Bosch

Packaging

)

approached

Autowrappers

with

a

deal

to

manufacture

their

range

of

HSU

flow-wrappers

at

the

Norwich

Factory

under

license.

this

agreement

continued

until

the

early

70s,

David

Mortimer

has

told

us

that

when

he

joined

Autowrappers

in

1968

they

were

still

building

the

HSUs

and

the

last

HSU

left

the

factory

in

1971

and

Auto

Wrappers were still supplying parts for the HSUs into the early 80s.

The

main

reason

that

the

HSU

was

discontinued

from

manufacture

at

Whiffler

Road,

was

that

during

this

time

the

AT

machine

had

been

redeveloped

into

the

Mk1

Versoflow

machine

and

the

Versoflow

was

proving

very

popular

with

customers,

and

because

of

this,

it

started

outselling

the

HSU

machines,

unfortunately

SIG

pack

were

not

pleased

that

Autowrappers

were

selling

more

of

the

Versoflow

machines

than

the

HSUs

and

saw

Autowrappers

as

a main competitor so promptly withdrew the license to manufacture.

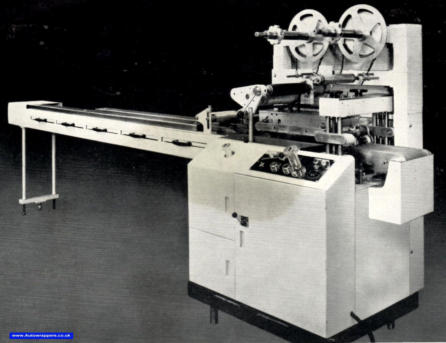

Photo Ref: AW0553 the AT Machine

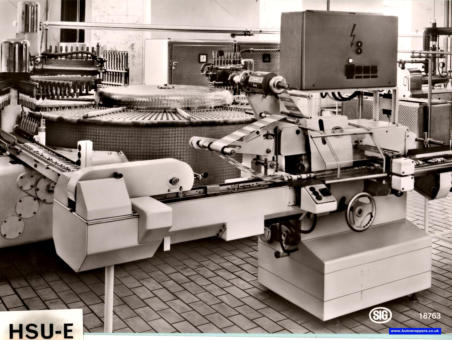

Photo Ref: AW0607 the SIG HSU Machine ( made under licence )

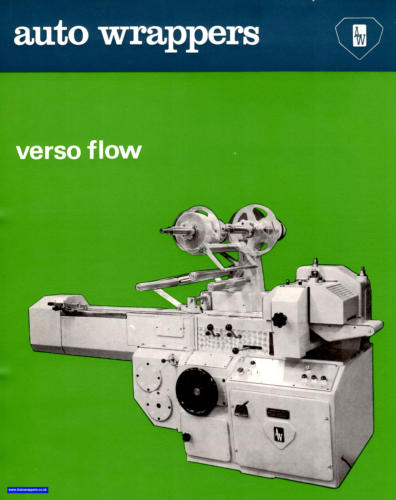

The New Versoflow Machine had replaced the AT machine and proved very popular with the customers at the time

Photo Ref: AW0246

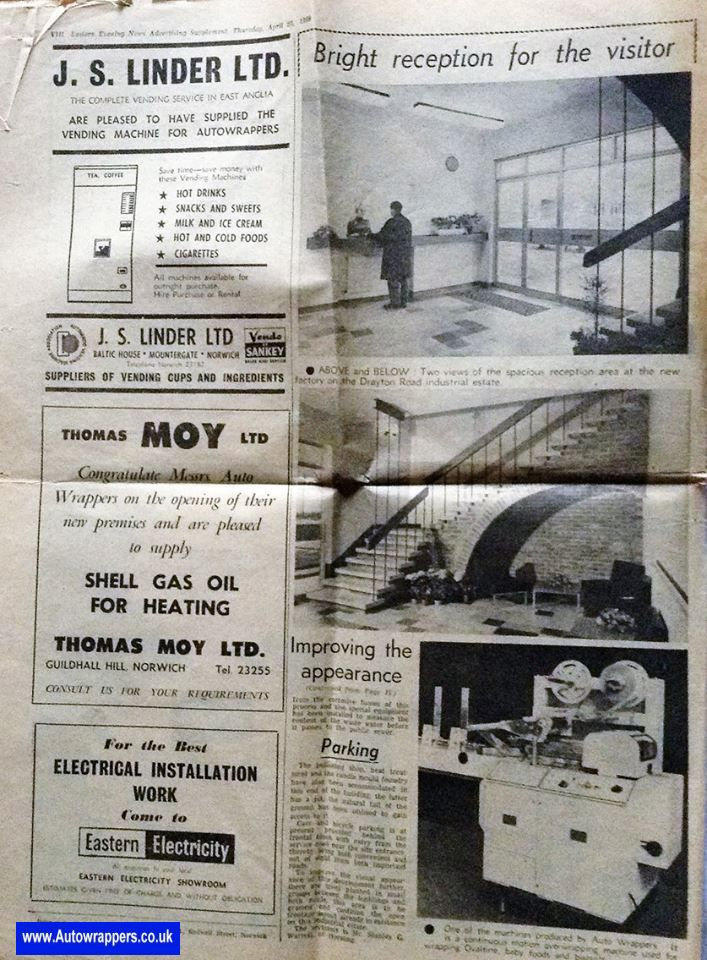

The

Reception

Area

at

Whiffler

Road

below,

although

not

considered

modern

by

todays

standards

was

the

leading

edge of design in 1967.it was such an Icon that It even had its own feature in the local Eastern Evening News

Photo Ref: AW0047 The Whiffler Road Reception Area

Photo Ref: AW0153 EEN Autowrappers reception feature

( Photo Courtesy of Geoff King / Richard Bull )

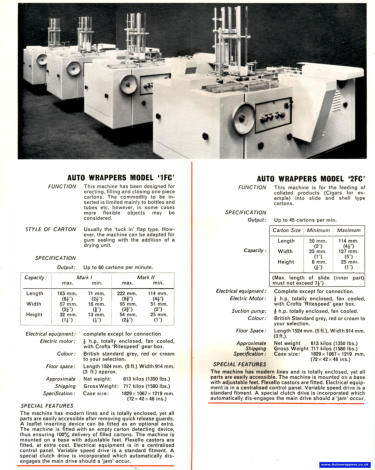

The

design

and

development

departments

were

expanding

the

range

of

machines

being

manufactured

and

also

developing

packaging

solutions

in

areas

that

had

previously

been

left

untouched

by

Autowrappers

in

the

past. And

very soon, the takeover of Tobenoil by GEI International would allow the company to diversify into other areas.